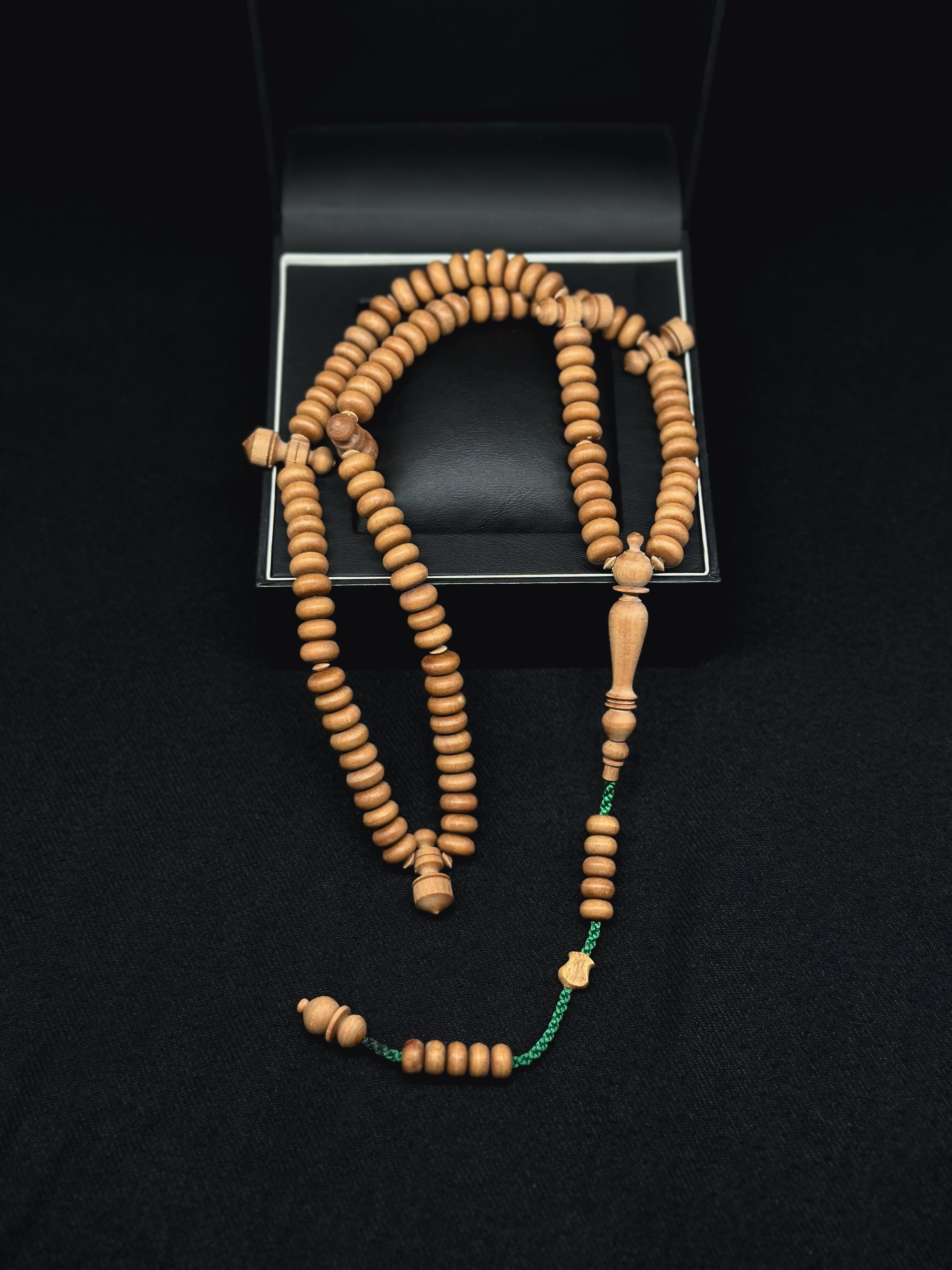

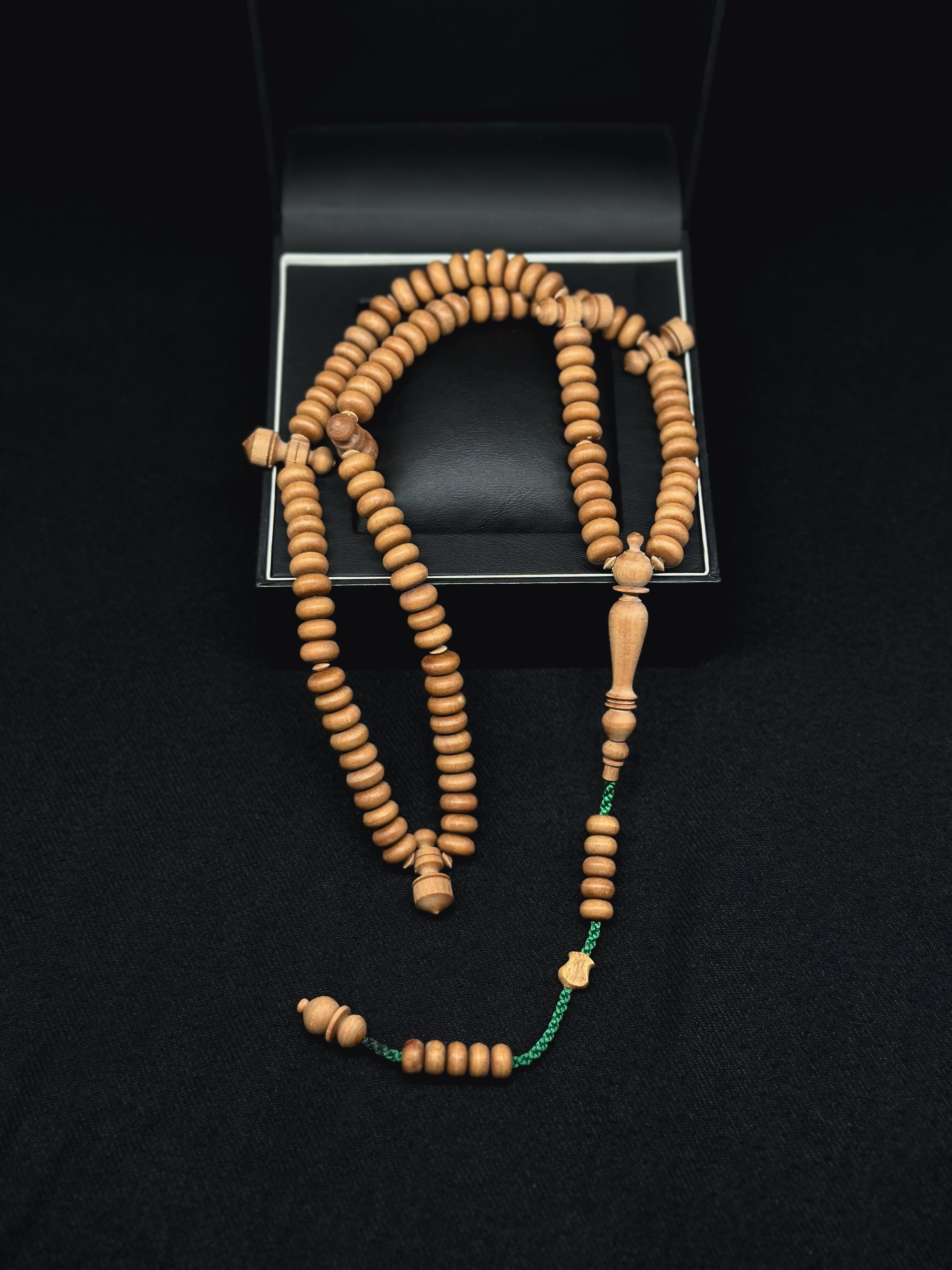

Adjustable Sandalwood Tasbih

The Material

Sandalwood, the ancient wood of the Vedas.

Origin

The oldest mention of Sandalwood dates back to the 5th century BCE Ancient India being mentioned in the Nirukta (a commentary on The Vedas). Since termites are unable to destroy the hard, aromatic heartwood, in India the tree has always been regarded as a protective tree whose scent drives out evil spirits.

History

Arab physicians first brought Sandalwood to Europe in the Middle Ages, appearing in Italian pharmacies at the beginning of the 15th century. The German naturalist, physician, and botanist Adam Lonitzer, mentioned Sandalwood in his work on herbs, The Kreuterbuch which was published in 1957. In there he described Sandalwood as being able to strengthen the heart, stomach & liver; cleansing blood and combating thirst and heat. In the middle of the 19th century, doctors treated gonorrhoea with Sandalwood.

In Ayurvedic medicine, Sandalwood Is described as being bitter, cooling, astringent and soothing. It is also mentioned that when its powder form is combined and mixed with rosewater, it is used as a remedy for inflammation and skin diseases. Sandalwood is indigenous to the tropical belt of the Indian Peninsular, Northern Australia & Malay Archipelago, where the majority of our sandalwood is imported from due to being one of the best qualities of natural sandalwood found in the entire world.

The Craft

Stage 1 – The Design:

The intricate design of the prayer beads are envisioned by the craftsman and a rough outline is sketched out onto a blank canvas. It is at this stage where the craftsman selects which materials they wish to utilise.

Stage 2 – Acquisition of the raw materials:

The hunt for the chosen materials begins and the wood is then ethically sourced and harvested from the finest and 100% organic of materials.

Stage 3 – The resize:

Once the material has been sourced it is then cut into smaller blanks and is now ready to begin onto the next stage of the process.

Stage 4 – The carving:

At this stage the beads, minarets, and separator pieces are carved into the desired shape and pattern. It is important to know that this entire method is done by hand; there are no molds, markers or guidelines. This is a skill and art form which requires exquisite hand co-ordination and takes a craftsman many years to learn and perfect.

Stage 5 – Excavating the holes:

Similar to the last stage this is a skill which requires years of practise. There are no markers or guidelines, and if the holes are off by even a fraction of a millimetre the prayer beads will not be aligned correctly. If the holes are too narrow this will result in the beads being stiff and difficult to move along the thread. If the holes are too wide this will result in the beads being extremely loose and difficult to use.

Stage 6 – Unmasking the natural beauty:

The materials are then sanded to bring out the beauty which is hidden deep within the beads. slowly each and every grain is uncovered and is manifested within each bead.

Stage 7 – The set up:

There are currently 3 main set up systems of how prayer beads are separated;

Shadhili – 100 beads separated using 3 dividers in the set up of 33/17/17/33.

Naqshbandi – 200 beads separated using 7 dividers in the set up of 7/11/40/70

Tijani – 100 beads separated using 5 dividers in the set up of 12/18/20.

Stage 8 – The stringing:

The beads are now finally ready to be stringed together using a durable thread. It is at this stage where the thread tension is decided on and with some can even be adjusted afterwards.

Stage 9 – The tassel:

This process takes hours to complete and is crucial in the overall look and design of the prayer beads.

Stage 10 – The inspection:

The set of prayer beads are now ready for one last inspection before they are to be released.

Specification

Bead Count: 100

Bead Size: 10mm

Material: Sandalwood

Choose options